Product Development

The first products of the collection were sampled and made in India through the talents and hard work of our India Design Team. Through regular video calls and email updates, we were able to maintain the collaborative nature of the design process.

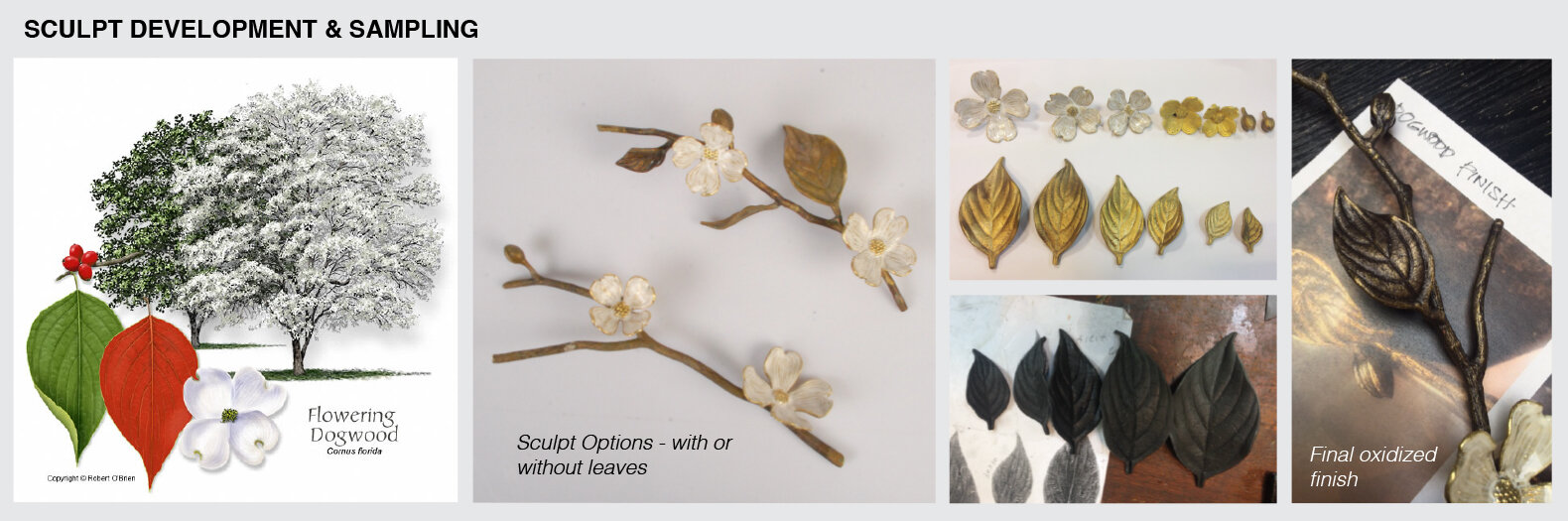

Sculpt Development

Based on drawings and actual images, the India Team began with rough sculpts of the elements necessary such as the flower, bud, leaf and stem. We also looked at the components various sizes to see which ones provided a good proportion. For Dogwood, we tried to figure out if the sculpt could work without leaves. We ended up including them.

Vase Development

The bodies of the vases were sampled first based on the drawings that were sent. We also placed them next to other existing vases for comparison. In some cases, different shapes are still considered to see if it really works with the sculpt. Fortunately, the Dogwood sculpts worked well with the shapes and we just had to work on finding the best composition for each piece. Mass production was also a big factor considered when composing the sculpt. We wanted to be sure it would not be too labor intensive and that the components used fall within the target cost.

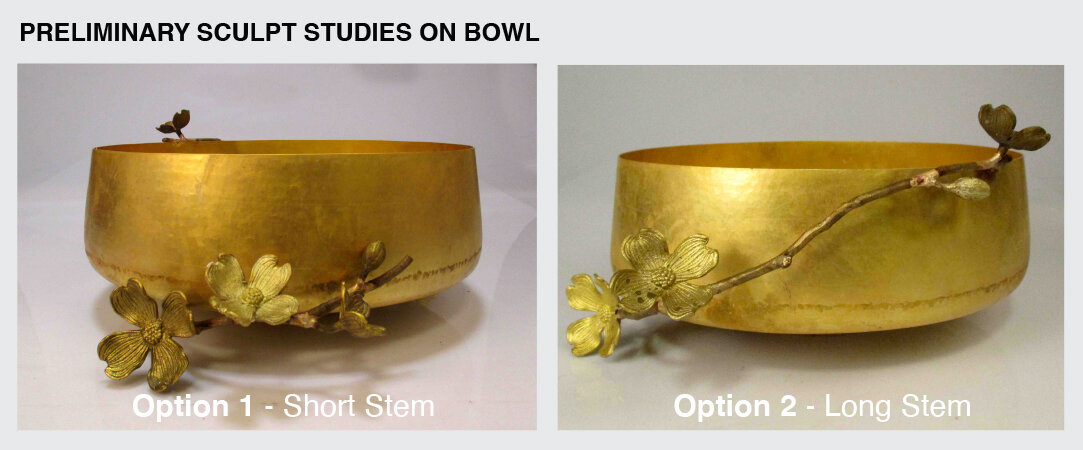

Bowl Development

We did a few trials on the 4 bowl samples. Even though we had finalized drawings indicating that only the low bowls would have the sculpt, we still tried it on all the pieces as it was the only time to really find out what they would look like. As with the vases, the India Team did several compositions for us to look at and give our suggestions. In addition we also added a small scoop that would go with the nut dish. We had designed its top to also resemble the silhouette of the collection.

Pitcher Development

Capacity is an additional key factor in creating pitchers. We wanted to make sure that it doesn’t get too heavy when filled especially if it were to be held and lifted by the limited ergonomics of our sculpted handles. We did size comparisons with our existing pitchers that functioned well as a reference on what works. We also had the similar conversations on getting the sculpt composition right. In this case, we made sure the twig was not too thick.

Design, Details & Concepts shown hereon are the exclusive property of Michael Aram Inc. and may not be reproduced or used without written consent of an officer of Michael Aram Inc.